What Makes the Small Mayonnaise Mixing Tank Stand Out?

The uniqueness of the mayonnaise mixing tank stems from its system configuration and the sophisticated process of mixing. It is one of the few machines in the industry that can produce high quality emulsions with less work effort. Be it a rich creamy mayonnaise or a smooth peanut butter spread, this tank makes sure that every batch has the appropriate consistency and texture.

Key Features:

- Electric Heating System: The tank is provided with an electric heating system which lightly heats the ingredient to the right temperature amalgamation. This guarantees an even blend of all components, which is needed to achieve the other half of the emulsified products, like mayonnaise.

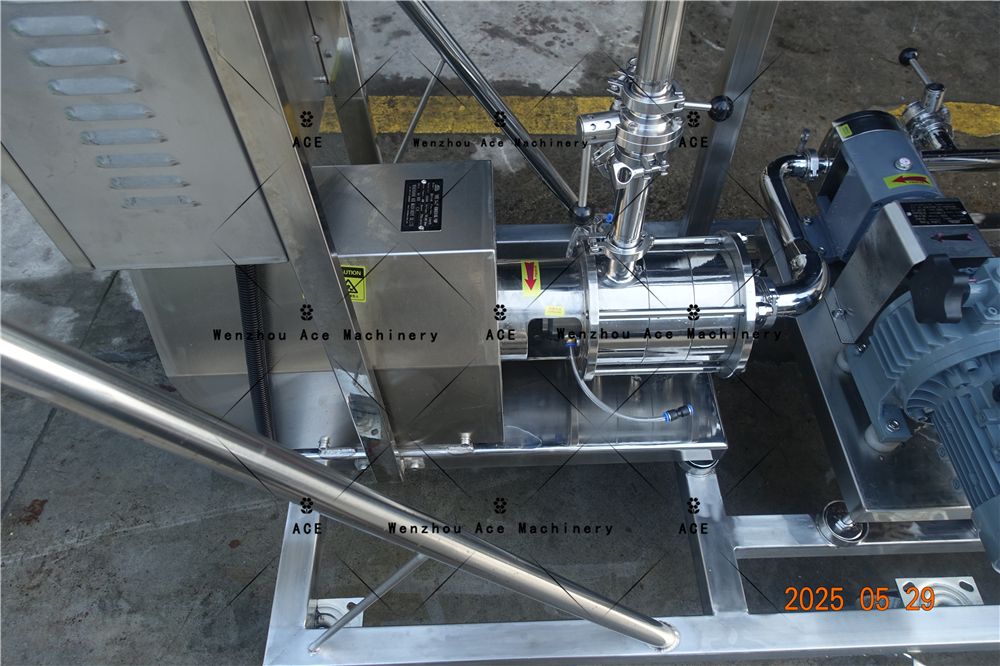

- Rotor Pump and Homogenizer: A homogenizer is used along with a rotor pump homogenizer. The rotor pump continually removes the mixture out of the tank and feeds it to the homogenizer, resulting in the emulsion. Due to the strong nature of the homogenizer, there are no clumps left, and the entire mixture is homogeneous in terms of all emulsions and sauces.

- Adaptable for Various Sauces: Apart from mayonnaise, this mixing tank can also process peanut butter, chili sauce, and more. The food products will go through appropriate mixing and emulsifying processes separately.

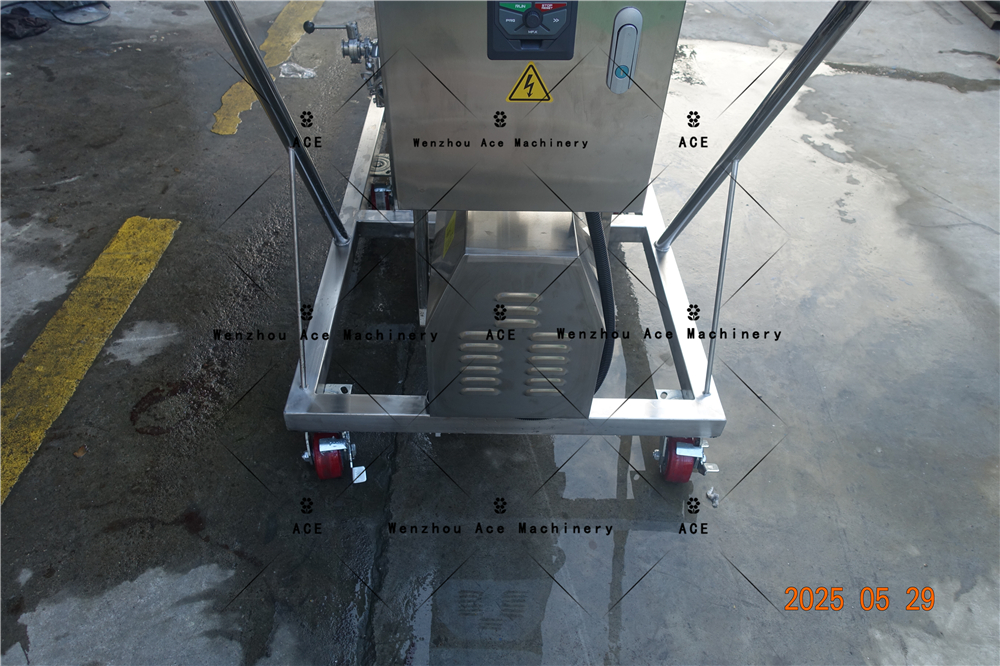

- Material Options: For your specific needs, the tank is offered in two stainless steel types:

- 316L Stainless Steel: This grade is highly resistant to corrosive damage, and thus suitable for acidic products such as mayonnaise which contains vinegar or lemon juice.

- 304 Stainless Steel: More affordable and resistant to impacts, this grade is suitable for food manufacturing equipment and food preparation vehicles.

- Voltage Flexibility: Different production regions and environments can utilize the mayonnaise mixing tank, as voltages from 110V up to 600V are offered. This flexibility caters to different power systems around the world.

What is The Process Flow of The Mayonnaise Mixing Tank?

The small mayonnaise mixing tank uses a cyclic, continuous process for emulsification. Here’s a breakdown of the steps:

How it Works:

- Step 1- Ingredient Addition: A mix of oil, egg yolk, vinegar, and spices are the raw ingredients to be fed into the mixing tank.

- Step 2 – Electric Heating: The oil and water-based ingredients are blended together after reaching the optimum temperature, which is maintained by the electric heating system.

- Mixing and Blending: The tank’s agitator starts mixing the ingredients thoroughly. The motorized rotor pump extracts the mixture and brings it to the homogenizer.

- Homogenization: The homogenizer pumps the mixture through a high-pressure system, turning it into a smooth, stable emulsion sauce.

- Continuous Cycle: This process iterates until the certain desired consistency is achieved, the tank’s design enables automated, constant production which eliminates the need for human labor and increasing productivity.

Applications and Use Cases

The small mayonnaise mixing tank is important for businesses producing sauces and spreads as it blends, easy to use and multifunctional. Some key Mayonnaise applications:

- Smooth and creamy mayonnaise with the required consistency.

- Peanut Butter: The emulsification process incorporated in the machine ensures that the peanut oil that naturally occurs is dissolved in the peanut butter paste so that the product remains constant without any floating oil.

- Tomato Ketchup: Prepares ketchup with a floating free uniform smooth viscosity suitable for retail packing.

- Chili Sauces and Hot Sauces: Best suited for hot sauces, which require that they be emulsified in order to obtain a smooth blend product of uniform consistency throughout.

Technical Specifications

- Capacity: Designed for small to medium scale production, adjustable to different needs.

- Material Options: 316L Stainless Steel, Corrosion resistant or 304 stainless steel, strong and lower price.

- Voltage Options: Available from 110 Volts to 600 Volts, depending on your region’s requirements.

- Heating System: Electric heating systems allows for careful regulation of temperature and quality of emulsification throughout the process.

- Emulsification Process: Performed by a combination of rotor pump and homogenizer for uniform viscosity.

Mayonnaise Mixing Tank Features and Its Benefits

- Rotor pump and homogenizer: Provides better products by assuring every batch meets the emulsification requirements for quality, uniformity, and consistency.

- Increased efficiency: Provides time savings due to the reduction of manual labor, helping businesses scale faster through the accumulation of lower production costs.

- Easy to clean: Manufacturers of food grade equipment ensure vessels and tanks made to hold and transform mixtures of liquid foods are easy to sanitize, guaranteeing maintenance of hygiene standards during food production processes.

- Energy efficiency: Effective use of electric heaters in comparison to other traditional thermal systems translates to reduced energy consumption, resulting in lowered overall costs through the effective use of electricity.

- Increased flexibility: In relation to other brands, the small mayonnaise mixing tank offers increased flexibility and can be altered to meet the client’s requirements for production volume, power supply, and any other desired specifications.

Frequently Asked Questions Regarding Smaller Mayonnaise Mixing Tanks

Can I use this tank for other types of sauces?

Yes, the tank is designed for mixing and processing a wide range of sauces and emulsified products such as peanut butter, ketchup, chili sauce, among others. This feature makes it useful in different food production processes.

What is the maximum voltage available for this machine?

The available voltage options for mayonnaise mixing tank are from 110V to 600V, competing with other machines in the market and making it more versatile to different regions of the world.

What materials are available for the tank?

The tank can be fabricated from 316L stainless steel for high corrosion resistance and more expensive options as well as more economical ones like 304 stainless steel which is stainless, food-grade and durable. Both these options while differing in characteristics provide safety standards.

Is the machine easy to clean?

Yes, as the entire surface of the machine is in contact with food smooth, bacteria and other microorganisms do not have surfaces to cling to, thereby ensuring hygiene and cleanliness. The design of the tank also permits ease in cleaning, enhancing hygiene.

Can I customize the mixing tank for my specific needs?

Of course! The customization options include those related to specific measurements such as size, voltage, materials, and others. Reach out to us for your tailored solutions and discuss with us these specifications so we can meet your production demands.

Begin Today!

With the small mayonnaise mixing tank, achieving efficient and high-quality blending for various sauces and emulsified products in the food production line has never been easier. This food processing machine not only meets the operational revamps demanded for mayonnaise production, but also for peanut butter and other sauces, providing the needed precision.

Reaching out to us will activate consultancy sessions for our mixing tank’s specifications. Thus, you will receive guidance on optimizing production processes, scaling your businesses, and custom designs tailored to specific industry requirements.